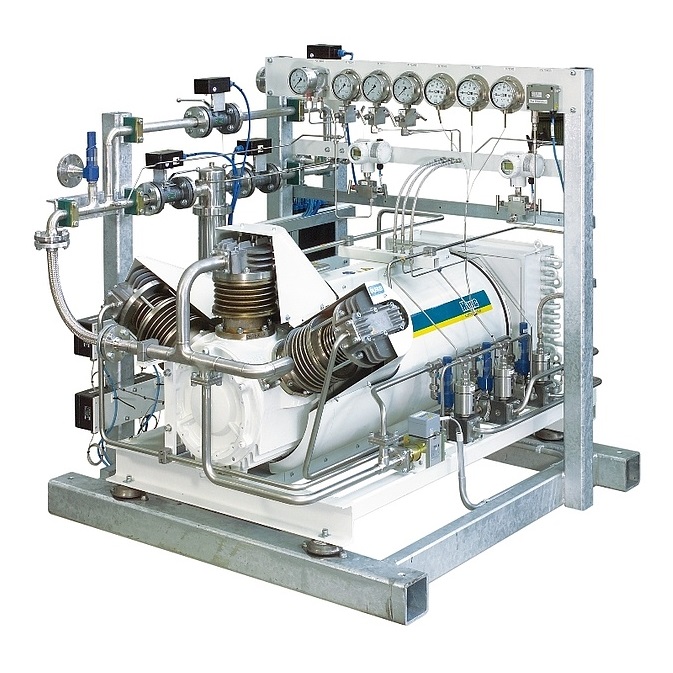

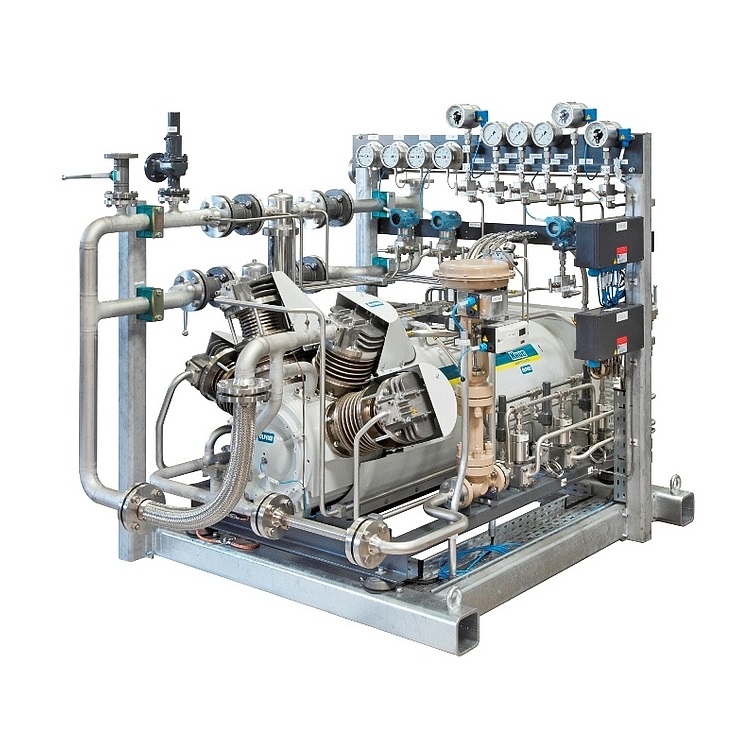

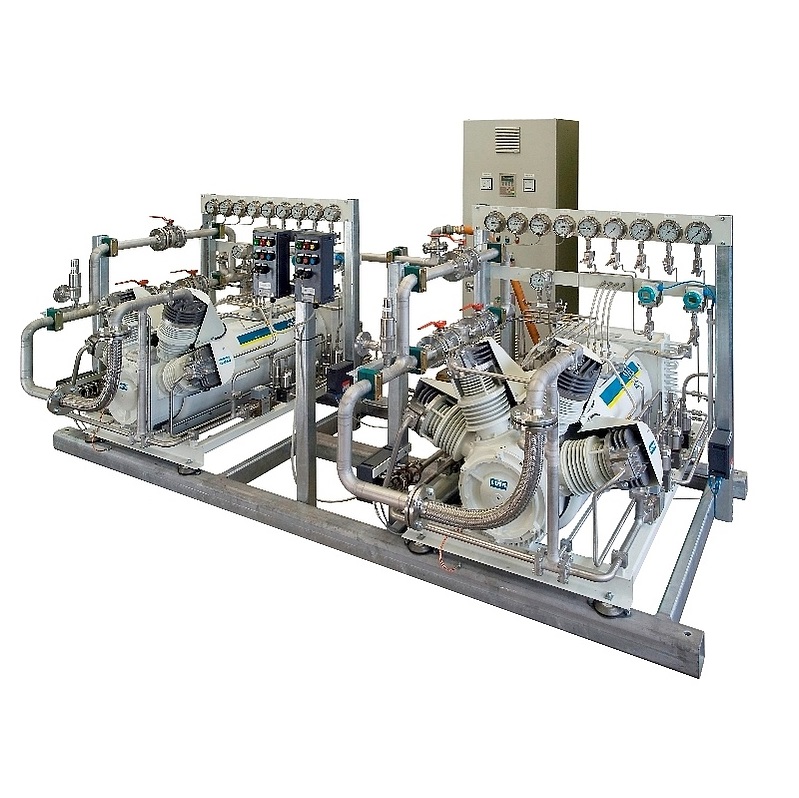

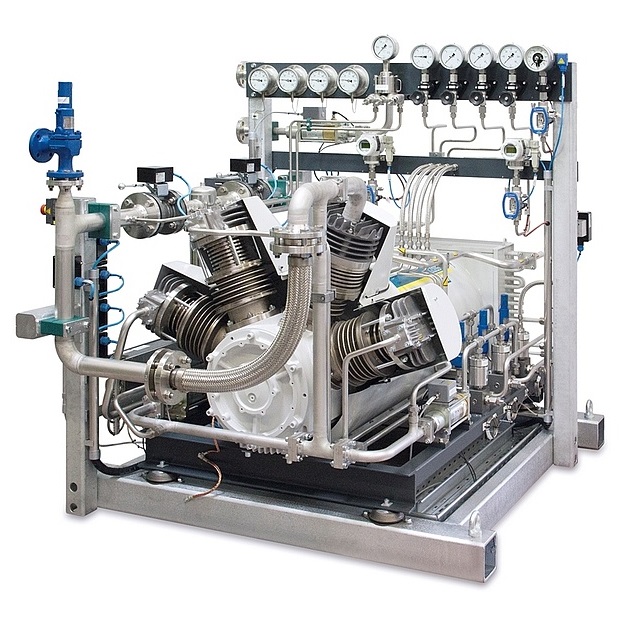

The HAUG.Sirius series has been used since 1973 for compression of air and gases and is a very mature compressor concept which, over the decades, has been continuously improved and developed. In the meantime, countless variants have been made available for different applications.HAUG.Sirius compressors with magnetic coupling were developed by HAUG Sauer and provide compression of gases without leaks. This hermetically sealed and entirely wear-free drive was first employed by HAUG Sauer in a piston compressor in 1989 and can be used for suction pressures up to 16 bar.

HAUG.Sirius compressors with shaft seals (TOD series) achieve, with the seals in new condition, a gas-tightness of 0.01 mbar l/s. This construction offers an economic option for compression of gases with atmospheric pressure.

The modular HAUG.Sirius compressor concept allows highly individual and cost-effective adaptation of the compressor configuration to the customer's requirements. This allows development of technically, commercially and energetically optimum solutions.

Features

- Complete oil-free piston compressor

- Gas-tight design with magnetic coupling

- HAUG.Sirius compressor block leak rate < 0.001 mbar l/s

- Air-cooled or water-cooled versions

- Motor power from 7.5 to 30 kW

- Rotary speed range 970 to 1450 1/min

- Suction pressure max. 16 bar

- Final discharge pressure max. 100 bar

- Modular cylinder configuration with cylinder diameter up to 180 mm

- Versions with 2, 3 or 4 cylinders with 1-, 2-, 3- or 4-stages execution

- Maximum flow rate at atmospheric intake pressure ca. 400 m3/h

- Booster compressor version flow rate max. ca. 1000 m3/h

- Explosion-proof compressor version (conform with ATEX zone 1 or zone 2)

- Very robust and long-lasting construction

- Compact and foundation-free installation

Product catalogue

Applications

- Carbon dioxide recovery, and carbon dioxide compression of supercritical CO2

- Nitrogen inert gas supply during ESD (Emergency Shut-Down)

- Recovery of Natural Gas (leakage gas)

- Oil-free booster compression of oxygen

- Oil-free booster compression of nitrogen and air (CDA = Clean Dry Air)

- Oil-free recovery and compression of SF6 gas

- Oil-free booster compression of natural gas and biomethane

- Oil-free compression of noble gases such as helium, argon

- Compression of refrigeration gas for example C3F8, R410 or ammonia

- Compression of syntheses gas for production of methane and hydrogen as well as power-to-gas applications